Description

In the fast-paced and high-pressure world of modern automobiles, every component plays a vital role in maintaining safety and optimal vehicle performance, and the braking system is undoubtedly the beating heart of this safety. Among the various components of this system, the brake pad serves as the point of contact and friction generation, bearing the critical responsibility of stopping the vehicle. Choosing the right brake pad, especially for vehicles that operate under diverse and sometimes demanding driving conditions, is a smart and essential decision.

Impact-pressed Ferodo brake pads, utilizing advanced technologies in design and manufacturing, have established themselves as a reliable and high-quality option in the market. These pads are not only engineered to meet safety standards, but are also designed with factors such as durability, noise reduction, and consistent performance across varying temperatures in mind, delivering a more confident and secure driving experience. In this article, we examine the features, advantages, and key considerations related to impact-pressed Ferodo brake pads to help you make a more informed choice.

Key Advantages of Impact-Pressed Ferodo Brake Pads

Thanks to their engineered design and high-quality raw materials, impact-pressed Ferodo brake pads significantly enhance braking performance. By providing stable and uniform friction during braking, even under emergency conditions and high temperatures, these pads deliver a quick and reliable response from the braking system. This characteristic not only increases passenger safety but also strengthens the driver’s confidence in vehicle control.

Another major strength of these brake pads is their durability and long service life. Their wear-resistant formulation allows them to remain effective for longer periods, reducing the need for frequent replacement. In addition, their design minimizes brake dust accumulation on the wheels, helping maintain a cleaner appearance. Ultimately, their quiet and vibration-free operation ensures a smoother and more comfortable driving experience.

Comparison with Conventional Brake Pads

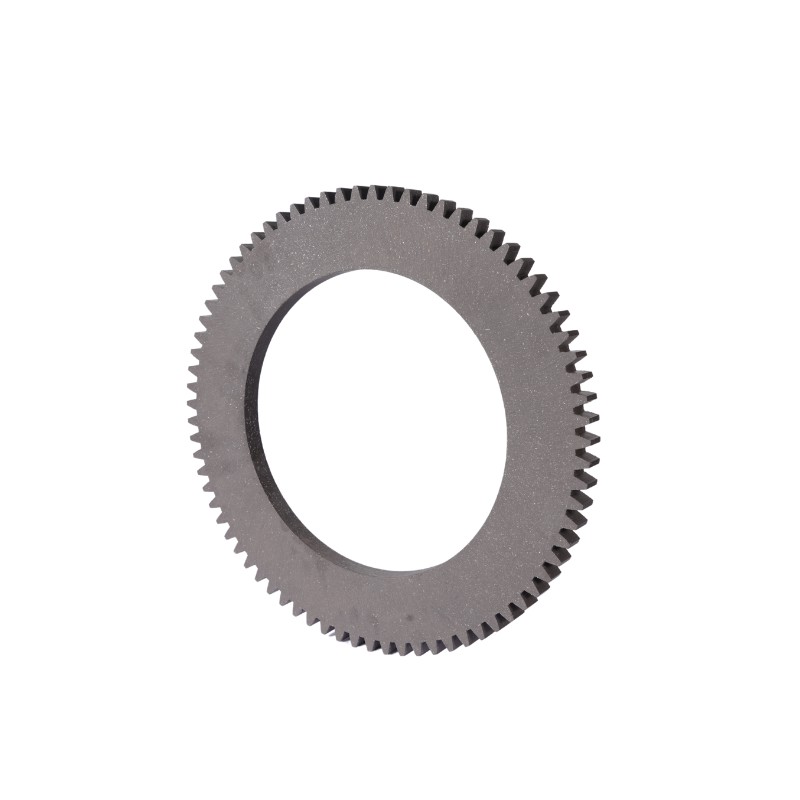

Unlike conventional brake pads, which are often manufactured using basic casting or forming methods, impact-pressed Ferodo brake pads are produced through an impact pressing process. This manufacturing method creates a denser and more uniform molecular structure within the friction material. As a result, internal compactness and mechanical strength are significantly increased, leading to more stable braking performance, reduced uneven wear, and a longer service life compared to standard brake pads.

In terms of braking performance, the differences are also substantial. Conventional brake pads may experience temporary friction loss, known as fade, at high temperatures, such as during prolonged or repeated braking on downhill roads. Impact-pressed Ferodo brake pads, however, offer much greater resistance to high heat due to their dense structure and superior materials, maintaining a more consistent friction coefficient across a wide temperature range. This feature not only enhances safety but also provides the driver with a greater sense of control and responsiveness during braking.