Description

Applications of the Friction Plate in Scania Machinery

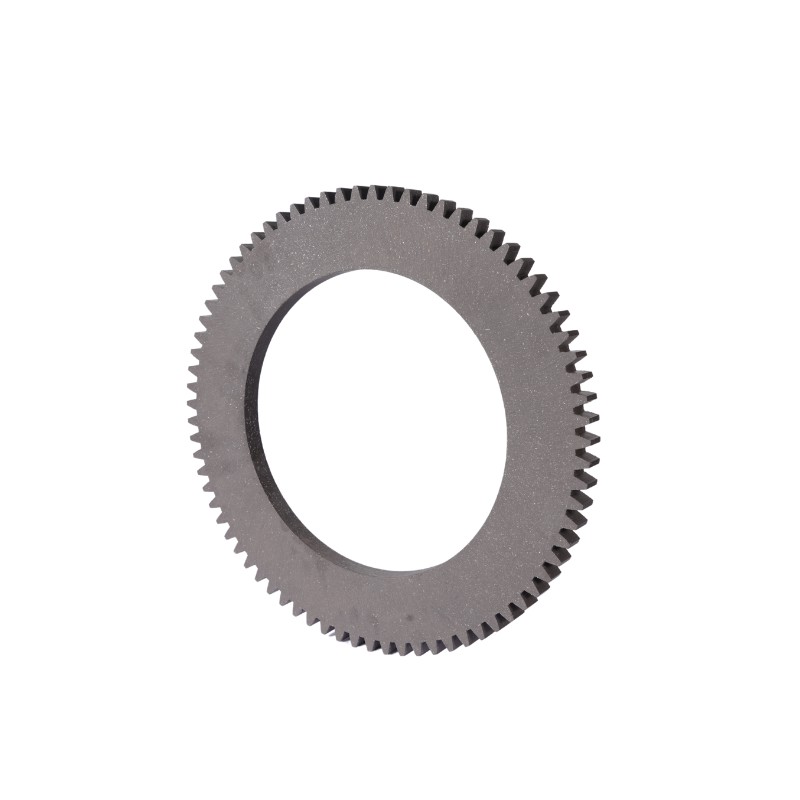

Friction plates are commonly used in heavy vehicles such as trucks, buses, and trailers. These components are essential parts of the braking and clutch systems in these vehicles. A friction plate is essentially a stainless steel piece coated with a material possessing frictional properties. This material, often a composite or fiber, is circularly mounted on the friction plate.

Scania, one of the major manufacturers of trucks and buses, uses high-quality friction plates in its vehicles. These plates, with high friction properties, have a significant impact on the performance of Scania trucks. Scania Bus 450 Friction Plate, Scania Bus 450 Friction Plate.

In Scania buses, friction plates are typically used for clutches and brakes. For the clutch, the friction plate is attached to a disc that separates from the friction plate when the clutch pedal is pressed. Without a quality friction plate, clutch performance can be compromised, which can seriously affect the truck’s operation.

Additionally, friction plates are used in the braking system of these vehicles, particularly in Scania’s hydraulic brakes. Without a quality friction plate, braking performance diminishes. Scania Bus 450 Friction Plate, Scania Bus 450 Friction Plate, Scania Bus 450 Friction Plate, Scania Bus 450 Friction Plate.

Importance of Maintenance and Repair of Scania Bus 450 Friction Plate

Ultimately, the Scania friction plate is a vital engine component essential for optimizing performance and extending engine lifespan. This plate endures pressure and friction with other parts and must be properly selected and installed according to operating conditions. Neglecting technical details and proper usage during installation and replacement can lead to reduced engine lifespan and performance issues.

To optimize the friction plate’s performance, proper maintenance and installation methods should be followed. Additionally, when replacement is necessary, use quality parts to prevent shortening the engine’s service life. By using the appropriate friction plate, you can enjoy optimized performance and extended engine longevity.

Mana Tormoz Mashin and Production of Scania Bus 450 Friction Plate

Mana Tormoz Mashin is proud to be the only manufacturer of friction plates in the country and has prioritized production of this product, providing customers with a high-quality item competitive with foreign products.

You can click here to view other friction plates produced by Mana Tormoz Mashin. Scania Bus 450 Friction Plate, Scania Bus 450 Friction Plate, Scania Bus 450 Friction Plate, Scania Bus 450 Friction Plate.

Also, click here to see other products of Mana Tormoz Mashin.